2/21/2025

In the electronics industry, the meticulous control of environmental conditions is an essential aspect to ensure the quality and reliability of products. While attention is often focused on preventing damage caused by excessive humidity, it is crucial to emphasize that an overly dry environment can also lead to significant issues, especially in SMT (Surface Mount Technology) production lines.

Among the implications of low humidity in SMT manufacturing processes, we find:

- The Generation of Electrostatic Charges (ESD): In a space with insufficient relative humidity, the air loses its ability to conduct electricity effectively, promoting the accumulation of electrostatic charges. This phenomenon poses a concrete risk to electronic components, which can suffer irreversible damage due to discharges, even those of an intensity imperceptible to the human eye.

- Issues Related to Solder Paste: Solder paste is an essential element in assembly processes and is particularly sensitive to environmental variations. In a dry environment, it can undergo premature drying, leading to negative consequences for adhesion to PCBs and the quality of solder joints.

- Fragility of Components and Materials: Low humidity can compromise the mechanical properties of certain components and materials used in electronics manufacturing. In particular, PCBs may become more fragile and vulnerable to microcracks during assembly and testing phases.

In order to mitigate the aforementioned risks, it is essential to implement an accurate control system within SMT departments, which should include:

- The continuous monitoring of air temperature and humidity levels.

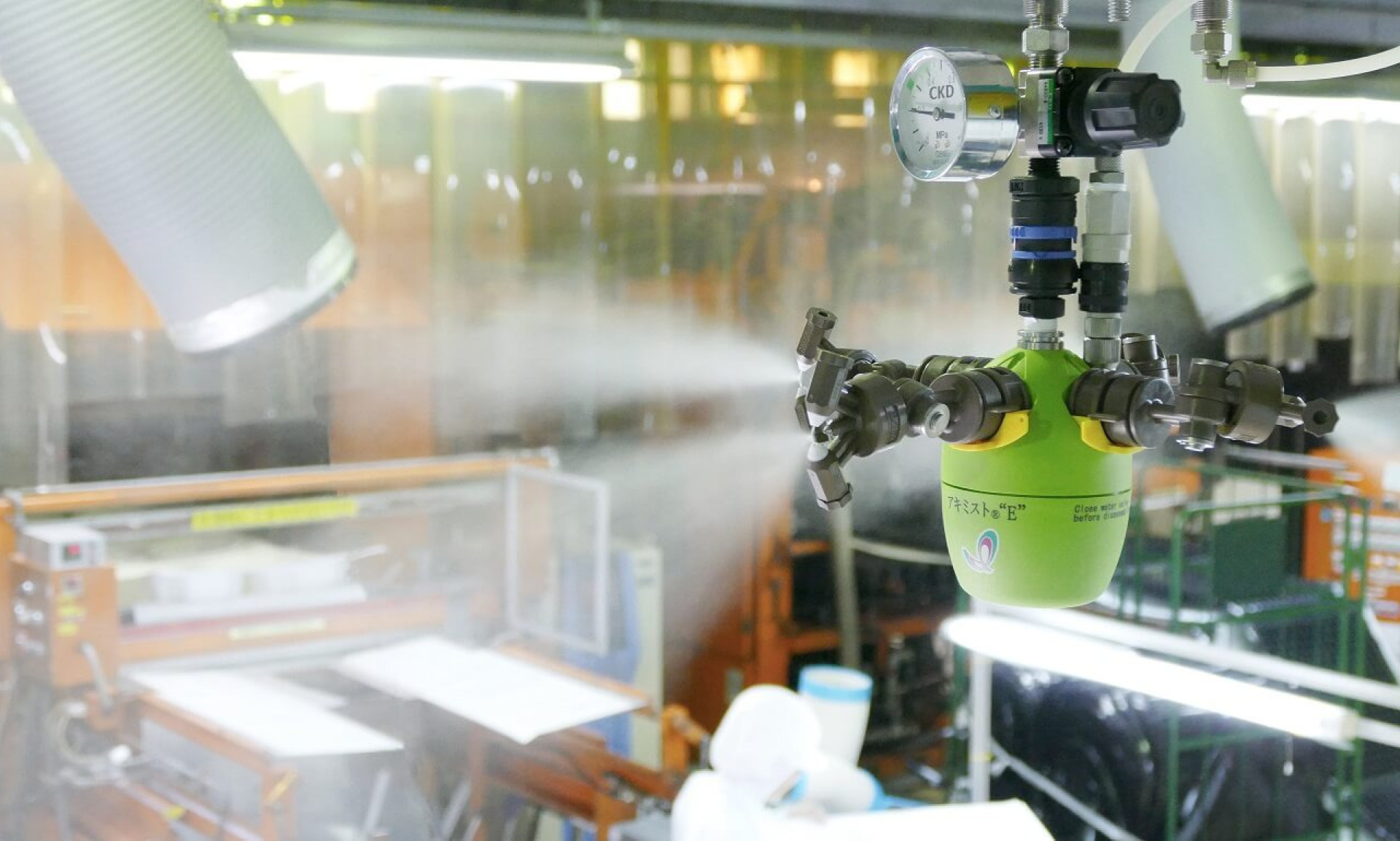

- The adoption of corrective measures, such as the use of humidifiers, to keep values within optimal limits.

- The training of production personnel on the risks and proper handling procedures for electronic components.

A production environment with an adequate humidity level is essential for the success of manufacturing processes in the electronics sector. Investing in cutting-edge control systems and adopting appropriate working practices helps preserve the integrity of components, optimize soldering quality, and ultimately ensure the reliability of the finished products.